Menu

Rheocasting is chosen to reach design targets.

The reason for this are the properties achieved by Using Rheocasting

It is not a new casting process, it is an melt preparation HPDC process

On top level the key driver is the design and production of more sustainable products why the interest from the market is growing day by day. Also the ease of implementation in combination with the secondary alloys that can be used with already made investments in production equipment and machines is making Rheocasting an attractive alternative for designers and foundries.

Examples of components of new markets are found as:

Truck industry

Decreased cost of thick walled components with good fatigue and strength properties where Rheocasting is compeeting successfully with low pressure die casting and permenent mold castings.

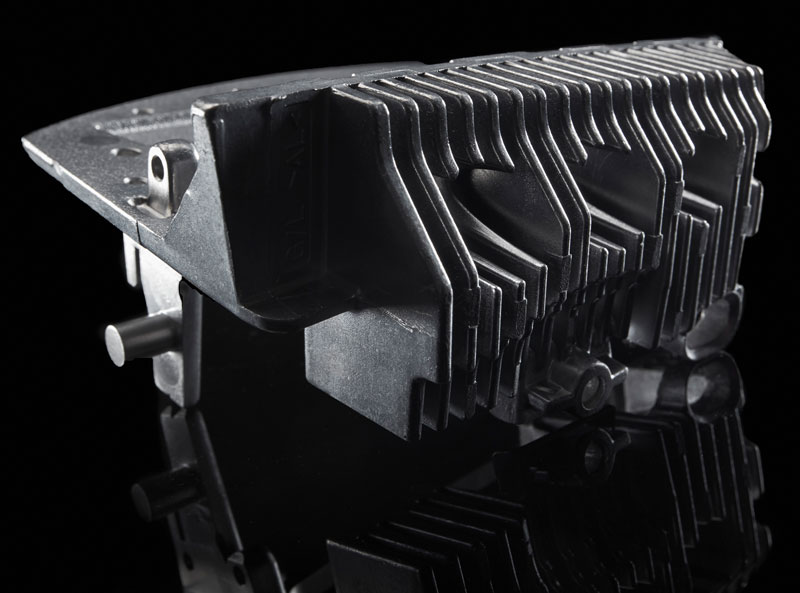

Telecom industry

Very high thermal conductivity, above +190 W/mK with advanced geometries as fin heights of 120 mm is challanging the use of extrussions and other processes and thus lowering the cost and weight of the component

Cars and EV’s

Chassis and very thin wall components for the automotive industry where elongation is a key. Using alloys that give high elongation, a complec shape and a low cost means by using smaller machines, a head to head competition with sheet metal drives expansion.

New markets evolve with Rheocasting

50% of the installed capacity is for production of components that are not possible to cast with todays methods. This means that an investment in Rheocasting is also an investment in sales and marketing that is not cannibalizing on current HPDC market.